SERVICES

Since 2014 we have been providing a complete Industrial Automation outsourcing service to industries in Brazil and worldwide. Our long experience includes robot programming, PLC, vision systems, simulations, training, preventive proof of concept and emergency maintenance.

PROGRAMMING

We carry out advanced programming following the customer's specifications, such as GAMP (Good Automated Manufacturing Practices) guidelines. Cienza can assist all phases of the project or only those that the client needs to reinforce in its field engineering team, such as:

- Offline programming and simulation

- Online programming at the factory

- Debugging and testing at the factory and on the customer's website

- TAF - Factory acceptance test

- TAC - Customer acceptance test

- Production and debug tracking

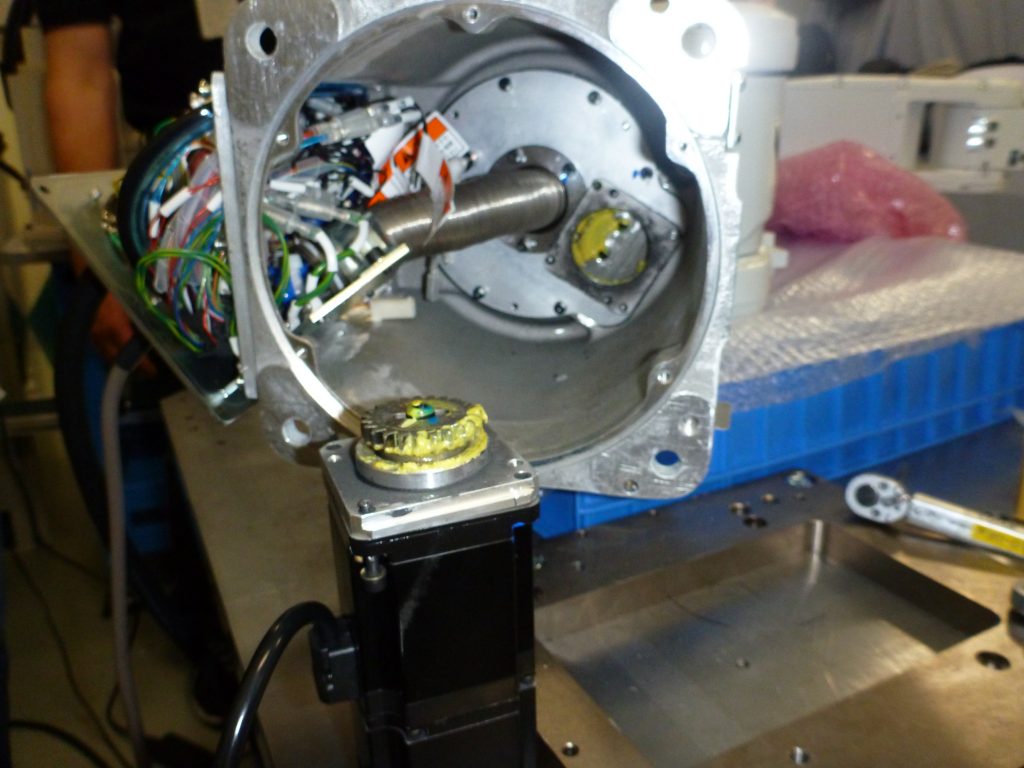

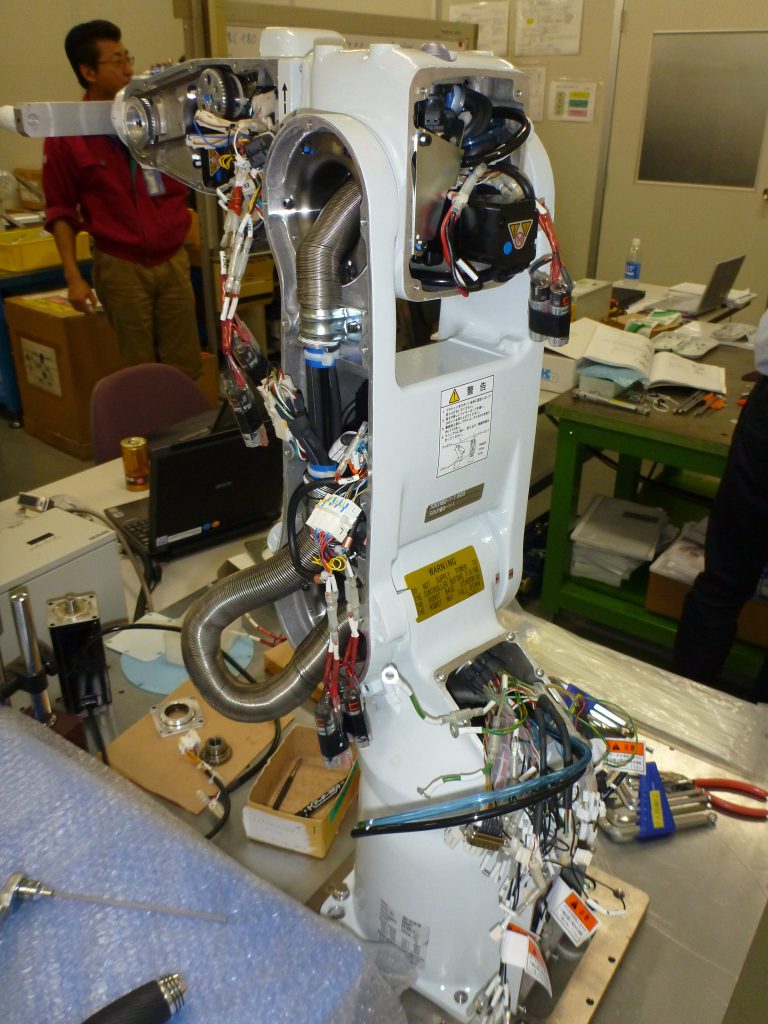

MAINTENANCE

Performed according to the manufacturer's specifications or equipment requirements. All of our maintenance service is performed according to the problems presented by the equipment, whatever it may be. Our service can be performed at our headquarters or at the location where the equipment is located.

TRAINING

Our training program was developed to serve the areas of operation, maintenance, programming and recycling. All training is conducted in person at the client. With flexible times and dates, according to the customer's need and availability.

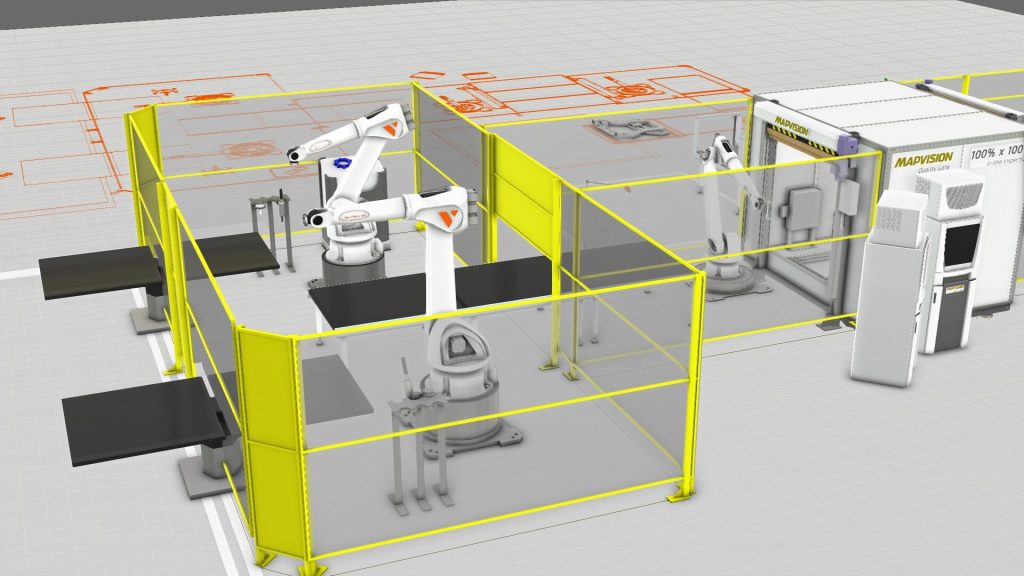

SIMULATION

We analyze, study and present the ideal model to perfectly meet your needs without having to interfere or hinder the company's real production.

POP - PROOF OF PRINCIPLE

We adjust your ideas through reliability tests, vision tests, precision and accuracy checking, cycle time checking, claw and tool checking, equipment integration and testing, performance comparison of different equipment, etc.